Free Craft How To Instructions

Stained Glass Tools

Glass Cutter

First and foremost, you'll need a good glass cutter. They come in a variety of shapes and styles, as well as price ranges.

This is the most common glass cutter, one that most people are familiar with...

The standard glass cutter shown above is most suited for making straight cuts. You can make curved cuts but it's a bit more difficult, especially when you get into smaller, more intricate pieces. For that task, you mightwant something like the Toyo Pencil Grip glass cutter...

The most important rule when using any glass cutter is making certain you keep it well oiled. With the standard glass cutter, you manually oil the cutting wheel. Other glass cutters - like the Toyo pencil grip - are filled with oil which automatically feeds as you're making cuts.

NOTE: Although they do sell oil specifically "made" for glass cutters, most any common lubricating oil will do (sewing machine oil, all-purpose oil, kerosene).

Soldering Iron

It's important to have a soldering iron with temperature control. Otherwise, the iron can get hot enough to melt through the lead came. To get started, you might want to simply purchase a soldering starter kit. That way, you'll be certain to have exactly what you need in order to work with stained glass.

Grozier (or similar pliers)

Used to break out scored glass and nibble away excess glass. Hold the pliers curved side up, using a rolling motion to gently scrape the glass edge against the serrated teeth. Use the tips in a chewing motion to nibble glass away, including deep inside curves.

Lead Knippers

Lead cutting pliers that will not squash the lead.

Solder and Flux

You can start with a one-pound spool of solder which is 60 percent tin and 40 percent lead. This combination melts quickly, but produces a strong bond.

Liquid flux is an absolute necessity. You need to brush this fluid on the lead just before soldering each joint. If you don't, the solder won't adhere properly.

There are several kinds of flux, but your best bet is either oleic acid or zinc and ammonium chloride.

Lead

Lead "came" is available in various sizes and shapes. Since you'll probably begin with small pieces of glass, you should purchase came which is no larger than 1/8" (3/32" is preferable, since it's easier to handle and looks nicer on small glass items).

In addition to lengths of came, you will need:

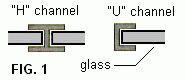

"H" channel

"H" channel

"U" channel

The "H" channel is used as a common border whenever two pieces of glass are butted together. The "U" channel is placed around the outer edges of the entire piece (FIG. 1).

Stained Glass Assembly

Cutting Glass